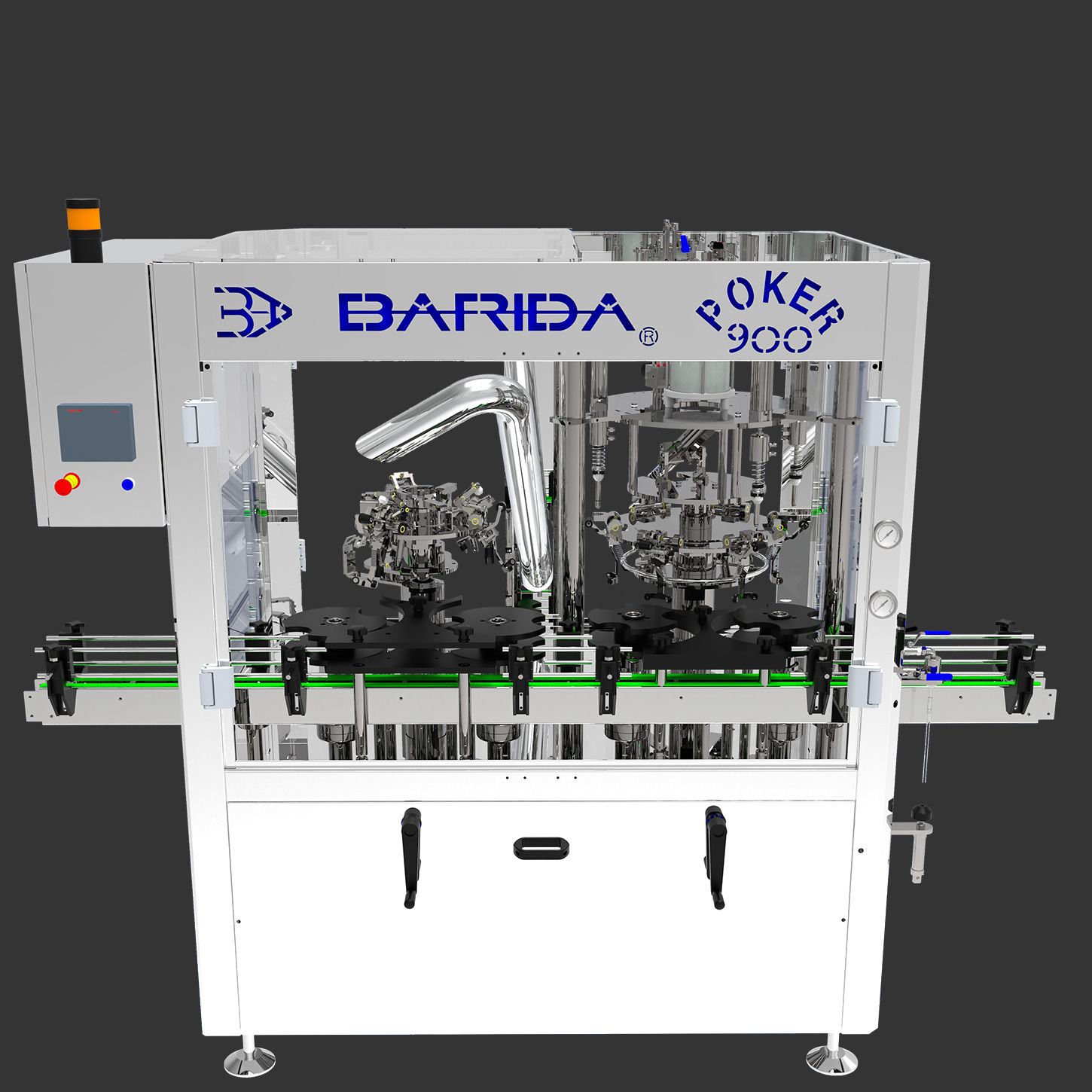

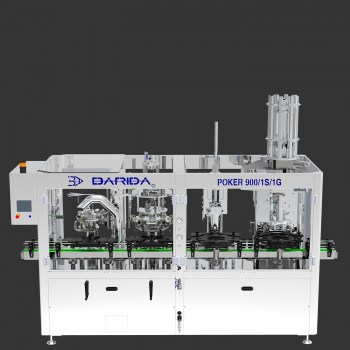

POKER 900

Machine for the processing of Classic Method Wines. Turrets mounted on a single steel structure to automatically perform the degorging, pouring, liqueur dosage and leveling operations. The monobloc consists mainly of two turrets, of which the first with continuous rotation and the second with intermittent rotation.

The first turret is dedicated exclusively to the disgorging operation: equipped with three bottle gripping / closing units, it overturns the bottle by 65 ° and then extracts the crown cap (conveyed into a collection tray inside the base).

The second turret has six work points (each of them equipped with a gripper) and performs three operations in a single rotation: filling, dosage of the liqueur and leveling with wine.

In the version with two motor units, the monobloc reaches an hourly production of 900 bottles / hour

TECHNICAL FEATURES

Working bottles: from 0.375 L to 1.5L

Inlet bottle neck washing device

Automatic adjustable dosage

Stainless steel taps

Simple, reliable and easily sanitized