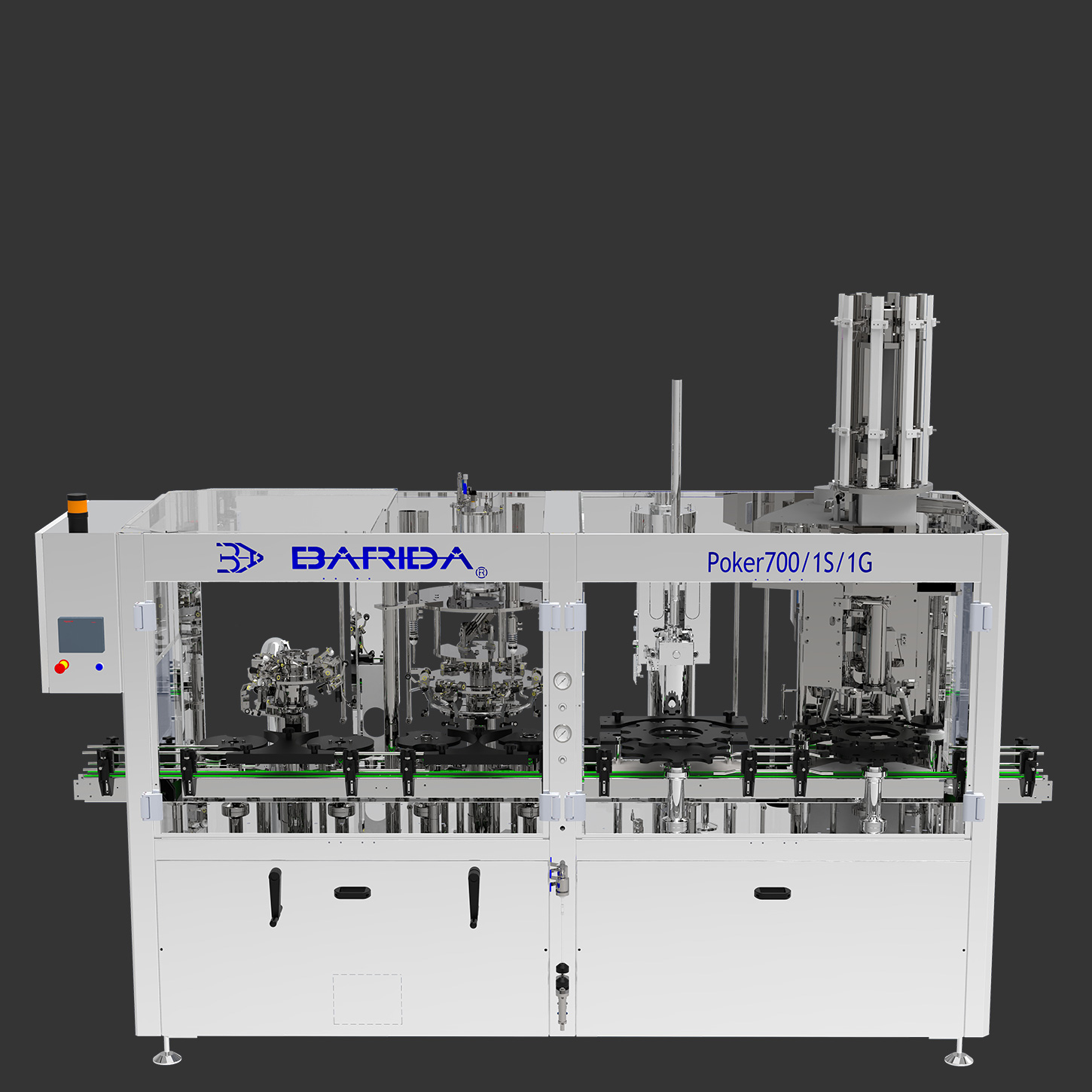

POKER 700/1S/1G

The monobloc has been designed to perform the operations foreseen in the last phase of wine processing in a completely automatic way according to the traditional method: degorgement, pouring, dosing with liquer d'expedition, leveling with wine and final capping with mushroom cap and cage.

Covered in stainless steel, it is composed of four main units:

- a continuous rotation turret dedicated to the disgorgement operation

- an intermittent rotating turret that performs the operations of pouring, dosage of the liqueur and leveling with wine

- a capping unit for the application of mushroom caps

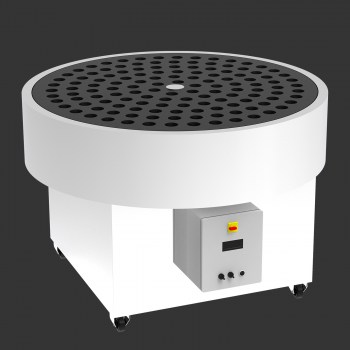

- a wire-hood unit for the application and closing of the wire-hoods

TECHNICAL FEATURES

Working bottles: from 0.375 L to 1.5L

Inlet bottle neck washing device

Automatic adjustable dosage

Stainless steel taps

Simple, reliable and easily sanitized

Automatic single-head capping and wire-hooding towers